Combined Heat and Power (CHP)

What is Cogeneration and Trigeneration, what does it do, how much does it save your business?

Energy Performance Model with Enerjisa

Enerjisa, your solution partner in Cogeneration and Trigeneration, enables you to generate energy at the location consumption, while developing a tailored business model for you, financing the investment and undertaking the performance risk of the system established.

Eliminating the energy losses in your facility, Enerjisa ensures savings!

Performance Is Our Responsibility

While our customers focus on their own areas of operation, we, at Enerjisa, provide end-to-end solution. At Enerjisa, we undertake the design, installation and commissioning of the system and ensure high performance.

While we provide financing through our Energy Performance Model, we also assume technical and operational risks. We offer an efficiency-oriented solution for the manufacturing industry and service sectors, which operate in various sectors, have high and balanced electricity and heat consumption throughout the day.

We also carry out operation and maintenance works for the project, and take the performance responsibility throughout the Energy Performance Contract (EPC). We always manage to be stand by our customers thanks to our expert team and well-established corporate structure.

Initial Investment Financing From Our Party

For your continuous and high-quality energy demand, Enerjisa uses its financial strength through our Energy Performance model to save you from seeking finance for the investment of Cogeneration and Trigeneration technologies; and enables you to carry out multiple investments that will contribute to your manufacturing/service costs without affecting your cash flow at the same time.

Our business model, which we have created together by taking into account your requirements, offers a long-term collaboration to ensure that you remain financially secure and that you do not miss out the opportunity of benefitting from your investment due to financial reasons.

Savings-Oriented Solution

With Cogeneration and Trigeneration systems, you can generate the energy you require at the location of consumption and establish a savings-oriented ecosystem that increases your efficiency. The losses in the transmission and distribution lines are prevented with the system established; hence, the benefits to be obtained from the system are increased.

Join the companies that generate the energy they require at the location of consumption by building Cogeneration or Trigeneration system, and generate your own high-quality electricity; so, reduce your dependence on the grid and get affected by the energy interruptions at the minimum.

Tailored Solutions

Industrial and service sectors require high electricity and heat energy consumption; therefore, Cogeneration and Trigeneration systems are the most efficient in these sectors. However, the requirements vary for each facility. Thanks to our solutions, we offer tailored design and operation options according to the requirements of our customers.

What is Cogeneration?

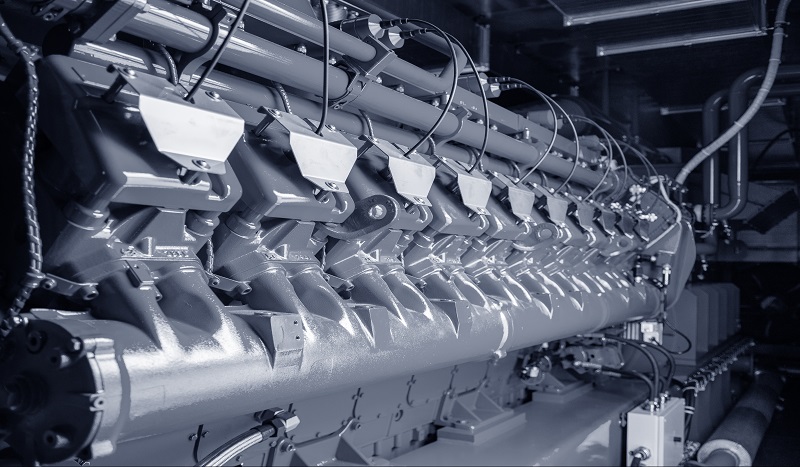

Cogeneration is the system in which electricity and heat energy are generated simultaneously. This system, which enables electricity and heat energy to be generated at the location of consumption, restores the thermal energy generated during electricity generation to the system and enables savings from energy. Moreover, generating at the location of consumption minimises the losses during energy transmission. Thus, electricity can be generated through a single system, buildings can be heated, and hot water requirements can be met. Thermal energy generated by cogeneration can also be used in industrial facilities and service sector where heat is required (steam, hot oil, etc.).

Cogeneration is also called ‘combined heat and power generation’ technology. The term ‘cogeneration’ is derived from ‘combined generation’. It refers to as the generation of electricity and heating energy required from a single source.

What are the Advantages of Cogeneration Systems?

Electricity and heat energy are lost until transmitted from power plants to the location of consumption. Cogeneration systems, on the other hand, generate electricity and heat at the location of consumption, and ensure that transmission and distribution losses are minimised. These systems not only prevent energy loss in distribution and transmission systems, but also eliminates the need for additional investment required in transmission and distribution systems. Furthermore, as cogeneration systems enable the conversion of waste heat into usable energy, they facilitate high-efficiency generation.

Cogeneration also provides efficient and economical use of energy by meeting the electricity and heat requirements from a single source (natural gas). Cogeneration helps to prevent environmental pollution by mitigating the carbon footprint of the facilities, and also reduces the external dependence of the facilities in energy supply. Fossil fuels used for energy generation in our world get more and more expensive each day. Cogeneration systems ensure the use of energy at maximum efficiency; hence, provide savings and contribute to the protection of environment.

What is Trigeneration?

Trigeneration is to provide the benefit of ‘cooling’ in addition to the cogeneration system that provides heat and electricity generation. Trigeneration systems generate electricity and heat energy in facilities as well as cold water for cooling systems. In other words, Trigeneration is the simultaneous generation of electricity, heating and cooling energies using a single energy source. Trigeneration systems provide savings and high energy efficiency to businesses that require seasonal or continuous cooling.

Cogeneration unit consists of a natural gas-powered gas engine equipped with an alternator. While this engine generates electricity, it also releases heat. With the recovery of this heat, the cogeneration system is completed. Trigeneration system, on the other hand, is built by adding thermal energy absorbing heat recovery system to the combined heat and power system (Cogeneration). Thermal energy is recovered in the heating system partially, the remnant is transferred to the cooling system by the absorption chiller. The absorption chillers use waste heat as an energy resource instead of electricity. Thus, your facility saves from all energy expenses.

How Much Do Cogeneration and Trigeneration Systems Save?

Gas turbines and engines that only generate electricity convert only 40% to 45% of the fuel they consume into electricity and cause a great loss of energy as waste heat. Cogeneration and Trigeneration systems save 30-40% in energy consumption by using this waste heat. In other words, a gas turbine or gas engine that generates only electricity converts only 40-45% of the fuel input to electricity, while the efficiency reaches 80-90% in cogeneration systems. Efficiency reaches about 95% in trigeneration systems.

What Are the Fuels Used in Cogeneration and Trigeneration Systems?

-

Fossil Fuels: Natural gas, LPG, LNG

-

Renewable Fuels: Biogas, Bio-diesel, Bio-mass

-

Waste heat

-

Solid wastes

-

Geothermal energy

Various equipment is procured and installed in the Cogeneration and Trigeneration plants of Enerjisa. The equipment is as follows:

-

Gas Turbine / Steam Turbine / Internal Combustion Engine

-

Generator / Alternator

-

Waste Heat Recovery Unit

-

Absorption Chillers

Where and In Which Sectors Are Cogeneration and Trigeneration Systems Used?

Cogeneration and Trigeneration systems can be applied to industrial facilities that constantly require heating and cooling, such as steam, hot water, hot gases / air, etc. The sectors where Cogeneration/Trigeneration technology is most efficient are the manufacturing industry and service sectors where electricity and heat consumption are high, stable and continuous throughout the day.

Cogeneration and Trigeneration systems are also valuable investments, particularly for hospitals that provide service 7/24. It is of great importance that hospitals and hotels continue their heating, cooling and electrical energy consumption without interruption. Therefore, Cogeneration and Trigeneration type systems provide great advantages, savings and efficiency in the energy cost of hospitals.

Cogeneration and Trigeneration systems are used in;

Textile industry

Food industry

Plastic and packaging industries

Paper industries

Hospitals

Hotels

Schools

Shopping Malls

Airports and Aviation service buildings

What Are the Advantages of Cogeneration and Trigeneration Systems?

- They generate energy at the location of consumption and increase energy efficiency.

1

- They provide 35-40% efficiency increase in electricity and heat generation compared to conventional (separate) power plants and boilers.2

- They reduce CO2 emission as the waste heat released into the atmosphere is recycled and used in conventional systems. Therefore, they provide an environmentally-friendly approach by reducing the carbon footprint of the facilities.3

- They save from electricity and heating costs.4

- The equipment used in Cogeneration and Trigeneration systems are durable and have low maintenance costs. 5

- The total energy expenditures of the businesses that build a Cogeneration or Trigeneration system decrease. Cogeneration Conversion is carried out without any disruption in the end-product or service quality.

6

- With decreasing energy costs, the competitiveness of the facility / business increases.

7 - Cogeneration and Trigeneration systems ensure energy supply assurance and protect against power cuts and disruptions with the optional solutions to be implemented. They enable energy continuity and increase in energy quality.

8

- They do not cause noise and sound pollution due to the low number of components in the system.

9

- Cogeneration and Trigeneration systems have low operating costs. These systems pay back the investment costs in a short time through energy continuity. 10

Cogeneration-Trigeneration Installation in 7 Steps

Consumption Analysis

The customer’s electricity bills and natural gas bills are requested and analysed. The previous hourly consumption data of the customer are analysed in detail via these bills. Legislative regulations, by-laws and technological compliance and other criteria are evaluated in this analysis. Enerjisa takes the responsibility of accurate system dimensioning if the past consumption data are provided in full. ‘Theoretical design and conformity assessment for business model’ stage is completed during this phase.

Field Analysis

Enerjisa teams visit the facility and conduct detailed field analysis. Electrical and mechanical infrastructure conformity, field and space conformity, which technology and equipment to choose for Cogeneration and Trigeneration systems, how to integrate the existing system with the Cogeneration or Trigeneration system, natural gas infrastructure are inspected.

Investment Analysis

The investment period is determined by calculating the return of investment and costs. Cost estimates, reimbursement plan and repayment mechanism are drawn at this stage.

Contract Signing

A long-term contract is signed between Enerjisa and the customer. The commitments of the customer and Enerjisa are determined in detail.

Procurement and Engineering Design

The equipment is selected and the method of procurement is determined, the engineering design of the project is prepared. Design stage is initiated to integrate the existing system with the Cogeneration and Trigeneration system.

Installation and Commissioning

Qualified teams of Enerjisa initiate installation, assembly and commissioning of the system. Throughout the contract period, the operational responsibility belongs to Enerjisa. Enerjisa undertakes completing the provisional acceptance procedures of TEDAŞ and commissioning the system.

Reporting, Monitoring and Maintenance: Continuous Performance Guarantee

All reporting, system monitoring and maintenance works are undertaken by Enerjisa, without any additional charges and in a completely transparent manner. Customers are periodically informed about the benefits and savings rates of Cogeneration or Trigeneration systems by means of benefit analysis and monthly reports.

Why Enerjisa?

Cogeneration and Trigeneration practices provided by Enerjisa reduce energy consumption, increase productivity and encourage sustainability. These systems contribute to the protection of environment by reducing energy costs and GHG emissions. Enerjisa performs the installation of systems without interrupting the usual operational activities while alleviating the financial burden of the investment with its innovative financing approach.

-

Aims for the system to be installed to operate at high efficiency.

-

Finances the investment partially or completely.

-

Undertakes every stage of the whole project.

-

Offers comprehensive services, including preliminary project report, field survey, detailed project design, procurement, installation, TEDAŞ acceptance, project management and consultancy services, etc.

-

Enables its customers to reduce their air pollution and to serve nature and the future with reduced carbon emissions through its Cogeneration and Trigeneration systems.

-

Undertakes technical and financial risks as part of the project.

Product Brochure

You can click to view our brochure where you can get information about Cogeneration and Trigeneration systems.

Let's Call You

Teşekkürler.